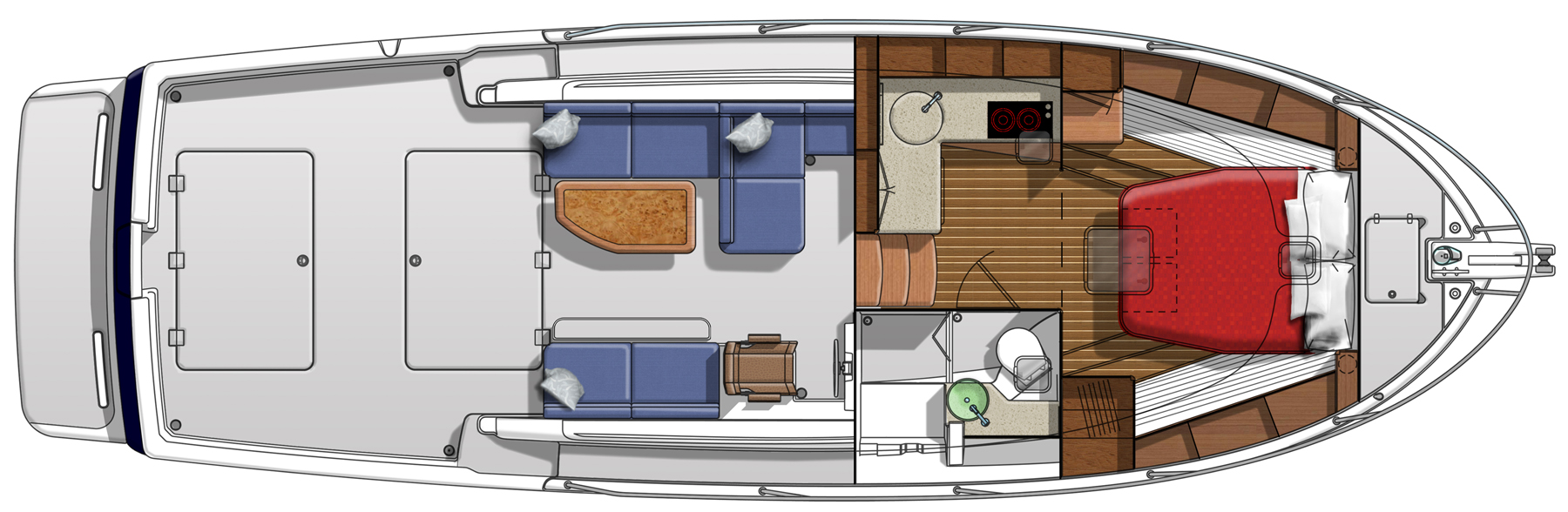

Back Cove yachts are known for the beautiful downeast design and fuel efficient engines but another charm to these boats is the fine woodwork hand crafted by Back Cove Associates based in Rockland Maine. The skills of these nine associates are second to none. They build everything from cabinets, to tables, to interior trim.

Back Cove interiors are all built from American grown cherry choosen because the wood is strong and ideal for furniture building. We also think it’s important that American Cherry is a renewable, sustainable, hardwood that is harvested in the Eastern United States.

To ensure the beautiful wood will need very little upkeep or maintenance, each finished product receives four coats of varnish (two sealer coast and 2 finish coats).

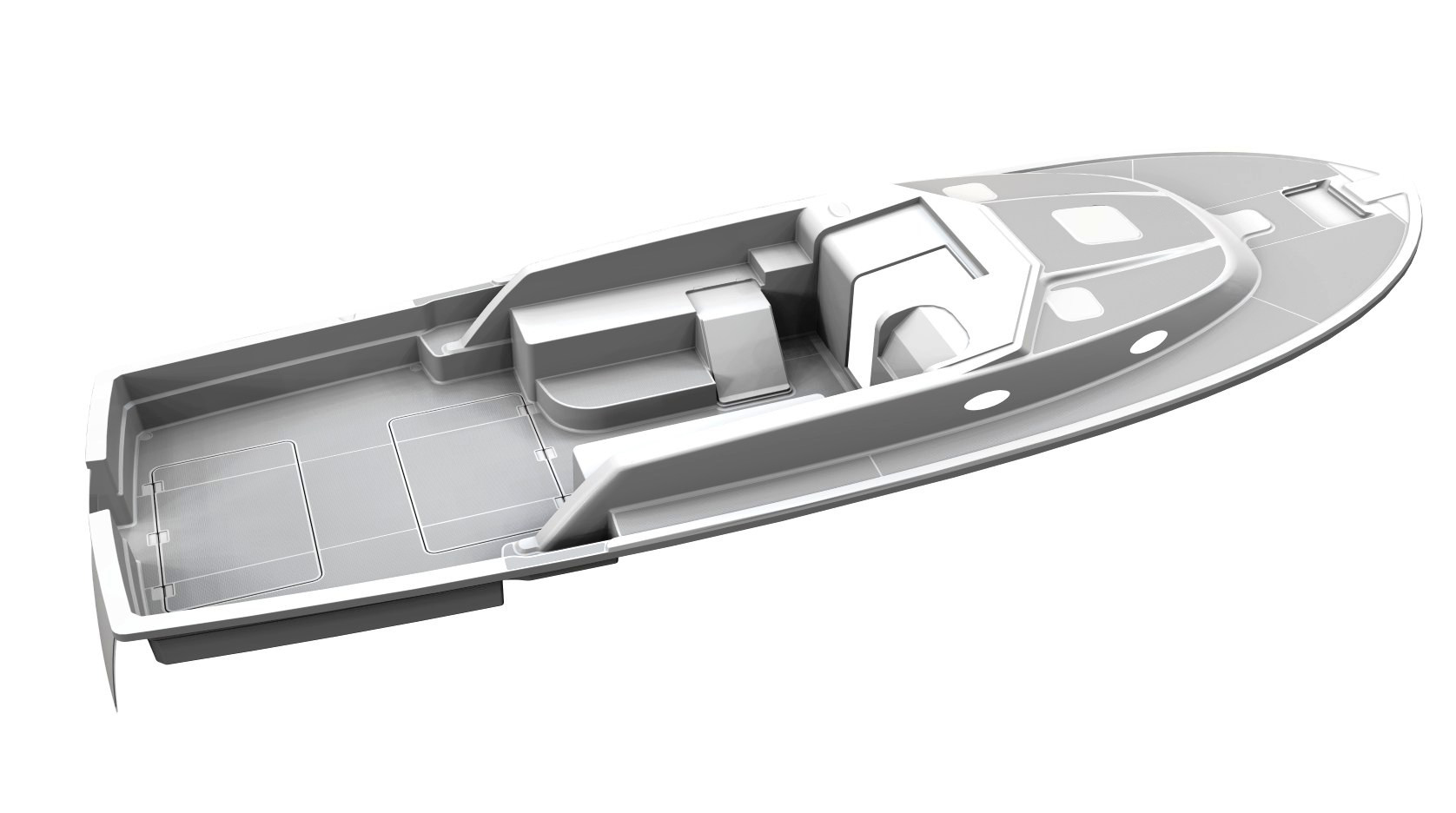

When a boat is ordered, the wood shop creates a “kit” for that particular hull. Once all the pieces are complete in the woodshop, they are installed into the boats as completed, varnished components; berths, lockers, bureaus, drawers and more.

The drawers are built of solid maple because it’s superior to an engineered wood product. Dovetail joinery on a drawer box represents a higher level of fit and finish.

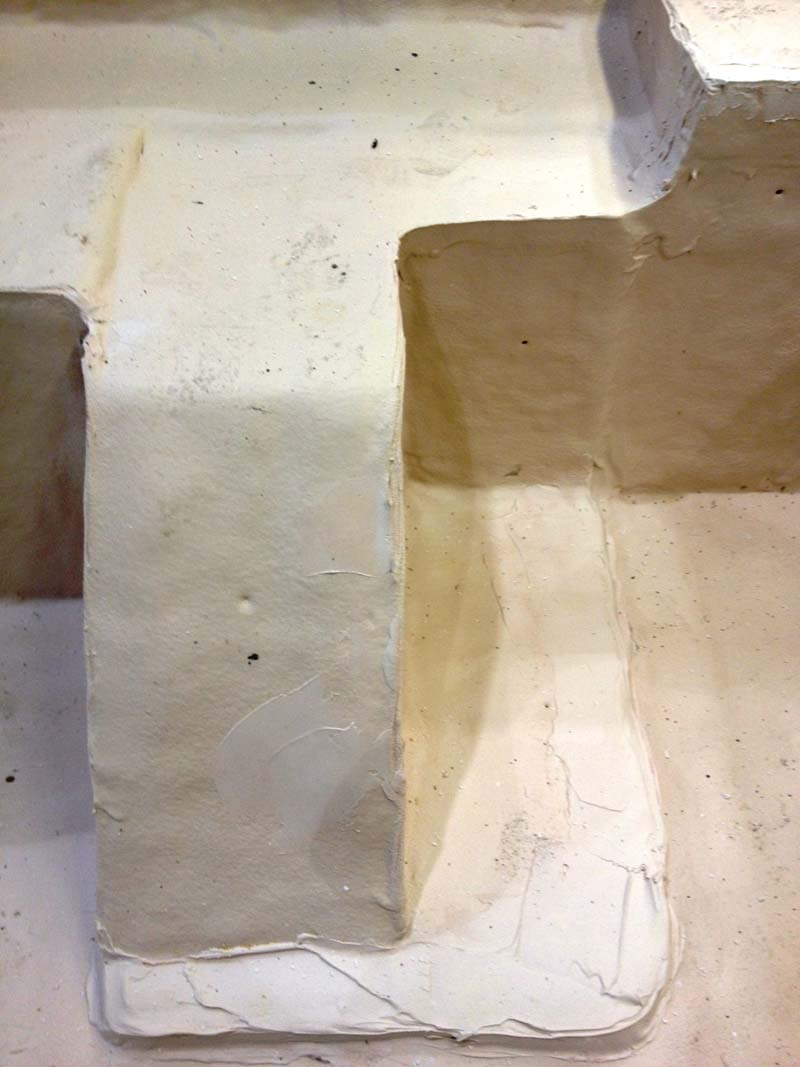

The image above is the beginnings of an island berth. On the left is the berth face with drawer openings. The piece on the right is one of the side supports which is shaped to fit the internal glass unit.

Wood shop labor represents roughly 15% of the total build hours. All wooden components are built by hand; we hand route parts and mill the various lumber profiles in house.

The interior of a Back Cove has beautiful built-in cabinetry that looks and feels elegant but is also practical to maintain for years to come.

Back Cove Yachts: Practical Elegance. From Maine.